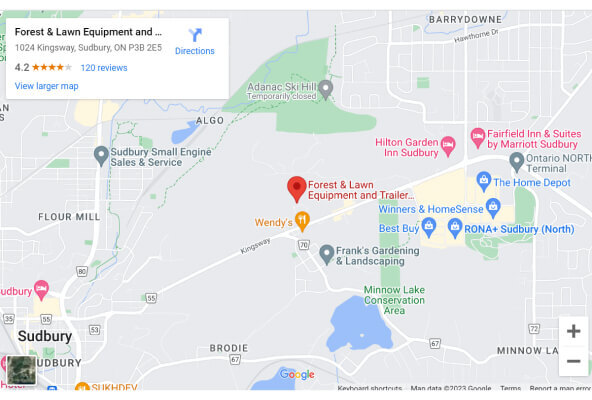

- Monday 8:30 AM - 5:00 PM

- Tuesday 8:30 AM - 5:00 PM

- Wednesday 8:30 AM - 5:00 PM

- Thursday 8:30 AM - 5:00 PM

- Friday 8:30 AM - 5:00 PM

- Saturday Closed

- Sunday Closed

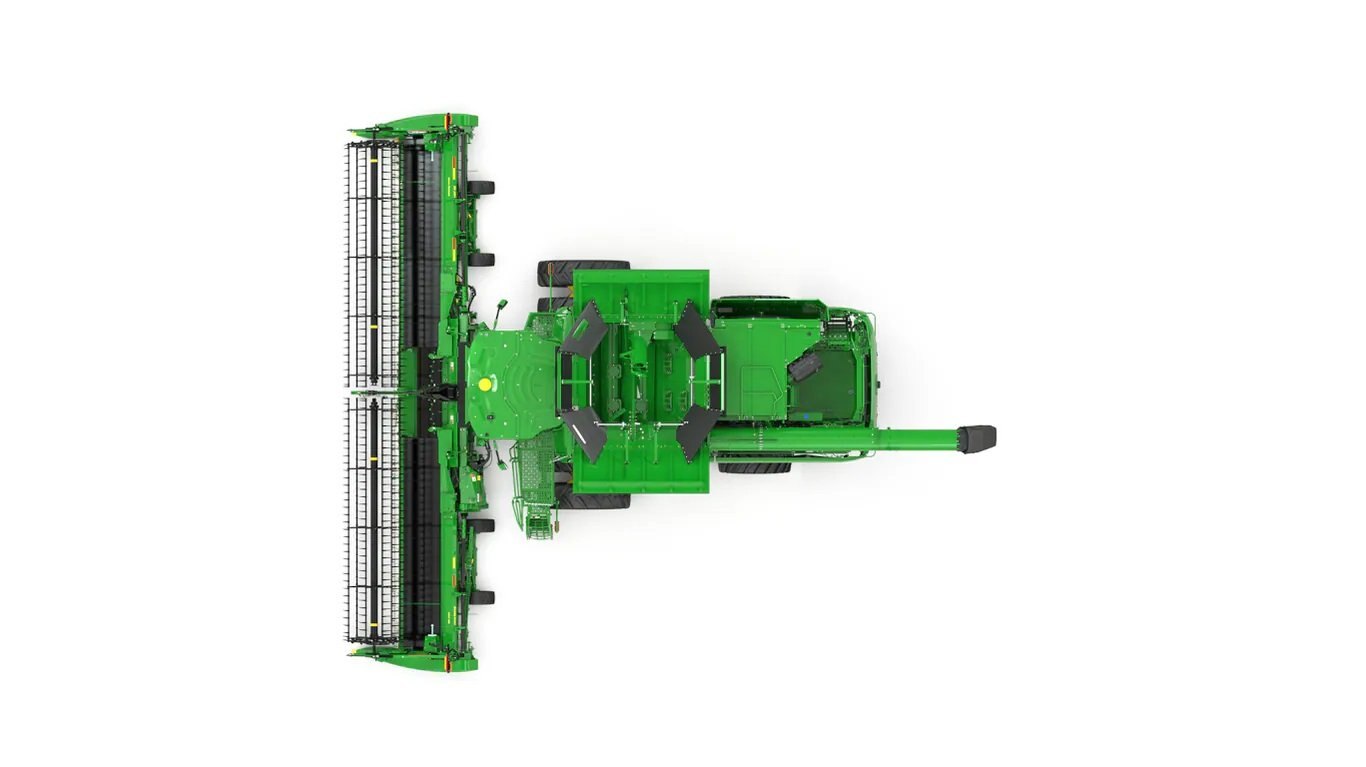

2025 John Deere S7 700

- Next generation John Deere JD9 9L Engine delivers more horsepower and faster unload than previous models

- More space, more comfort and more visibility1, with the same cab as the X9

- Integrated G5Plus CommandCenter™ Display, StarFire™ Receiver and JDLink™ modem

- Available Predictive Ground Speed and Harvest Settings Automation

|

|

Truly tough conditions demand more than simple solutions. Rather than slightly improve performance in rice, canola, wheat, barley, oats, or other tough small grains, John Deere S Series Combines set new capacity standards with four crucial components: Active Concave Isolation, a high-performance feeder house, heavy-duty interrupter grates with integrated interrupters, and the variable-stream rotor. When you’re looking at a storm on the radar and you don’t have time to spare, you can run full throttle and still put your toughest crop into the machine without any issues.

|

|

The faster you can get to – and into – your fields, the more productive you are. John Deere S Series Combines make it easy. Tracks help you get into the field sooner and finish faster. The ProDrive™ system lets you smoothly shift between two speed ranges (field and transport) with the push of a button; you’ll no longer have to stop to shift when going up or down hills or when you’re exiting a field.

|

| Engine type | John Deere PowerTech™ PSS engine 9.0 L 548 cu in. |

|---|---|

| Rated power | 249 kW 333 hp |

| Fuel capacity | 950 L 250 gal. |

| Rotor length | 312 cm 123 in. |

| Rotor diameter | 76.2 cm 30 in. |

| Concave area | 1.1 m2

11.8 sq ft |

| Separating area | 1.54 m2

16.6 sq ft |

| Total cleaning area (louvered) | 5.1 m2

54.9 sq ft |

| Grain tank size | 10,600 L 300 bu |

| Peak unloading rate | 127 L/s 3.6 bu/sec |

| Engine type | John Deere PowerTech PSS engine 9.0 L 548 cu in. |

|---|---|

| Emission level | Final Tier 4 / Tier 2 (Australia/New Zealand) |

| Rated speed | 2,200 rpm |

| Rated power | 249 kW 333 hp |

| Power boost @ rated speed | 25 kW 34 hp |

| Fuel capacity | 950 L 250 gal. |

| Drive type | Fixed or variable or multi-speed |

|---|---|

| Conveyor chain slat type | Cast iron |

| Width | 139.7 cm 55 in. |

| Length | 172.5 cm 67.9 in. |

| Feed Accelerator, Stone Trap (FAST) | Reverser Standard Standard |

| Front chaffer | 0.5 m2

5.4 sq ft |

|---|---|

| Chaffer | 2.5 m2

26.9 sq ft |

| Sieve area | 2.1 m2

22.6 sq ft |

| Total cleaning area (louvered) | 5.1 m2

54.9 sq ft |

| Cleaning fan speed | 620-1,350 rpm |

| Grain tank size | 10,600 L 300 bu |

|---|---|

| Unloading auger length | 6.9, 7.9 or 8.7 m 22.5, 26 or 28.5 ft |

| Peak unloading rate | 127 L/s 3.6 bu/sec |

| Total machine | 18,950 kg 41,778 lb |

|---|

| Country | USA, East Moline, Illinois |

|---|

| Date collected | 27-April-2018 |

|---|