- Monday 8:30 AM - 5:00 PM

- Tuesday 8:30 AM - 5:00 PM

- Wednesday 8:30 AM - 5:00 PM

- Thursday 8:30 AM - 5:00 PM

- Friday 8:30 AM - 5:00 PM

- Saturday Closed

- Sunday Closed

2024 John Deere 375A

↵

|

|

Backhoe performance To ensure optimum performance, the tractor's hydraulic flow and increased system pressure are matched with the backhoe's system enhancing the digging force and overall performance. Key features include:

|

|

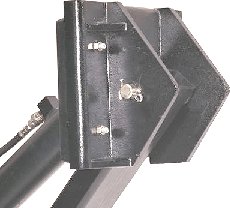

The backhoe's mainframe fits into rear mounting brackets installed on the tractor. This provides the following important features:

INSTALLATION

REMOVAL

|

|

Operator comfort features The controls on the backhoe operator console are arranged for optimal comfort, especially important for workdays.

|

|

Serviceability and angle of departure

|

|

The boom and dipper are designed with the strength to handle the large loads put on these powerful backhoes. The boom cylinder is run externally on the 375A Backhoe. This provides better serviceability. |

|

Powerful 170-degree swing DOUBLE-ACTING CYLINDER SWING SYSTEMThe backhoe features twin hydraulic cylinders to control the swing.

|

|

|

|

Convenient and easy operation

|

|

Rubber stabilizer pads are available as an attachment. The pads are popular when operating the backhoe on hard surfaces.

|

|

Variety of buckets to match digging requirements Buckets are available in a variety of sizes to fit the job for greater productivity.

|

| Digging depth | 94 in. 2.38 m |

|---|---|

| SAE dipperstick digging force | 2041 lb 9078 N |

| SAE bucket digging force | 3063 lb 13624 N |

| Swing arc | 170 degree (angle) |

| Boom lift capacity | 595 lb 270 kg |

| Transport height | 85 in. 2.16 m |

| Stabilizers spread width, up | 66 in. 1.67 m |

| Stabilizers spread width, down | 89 in. 2.26 m |

| Bucket widths | 9 in. (228 mm) 12 in. (305 mm) 16 in. (406 mm) 18 in. heavy duty (457 mm) 20 in. (508 mm) 24 in. (610 mm) |

| Swing arc | 170 degree (angle) |

|---|---|

| Bucket rotation | 180 degree (angle) |

| Boom lift capacity | 595 lb 270 kg |

| SAE dipperstick digging force | 2041 lb 9078 N |

| SAE bucket digging force | 3063 lb 13624 N |

| Bucket control main relief valve pressure | 2250 psi 17580 kPa |

| Digging depth | 94 in. 2.38 m |

|---|---|

| Loading height (bucket at 60 degrees) | 68 in. 1.72 m |

| Reach from center line of swing pivot | 129 in. 3.27 m |

| Transport height | 85 in. 2.16 m |

| Loading reach (bucket at 60 degrees) | 44 in. 1.11 m |

| Transport overhang | 48 in. 1.22 m |

| Undercut | 17.5 in. 0.44 m |

| Stabilizer type | Stabilizers spread width, up 66 in. 1.67 m Stabilizers spread width, down 89 in. 2.26 m |

| With 0.4-m (16-in.) bucket | 1250 lb 567 kg |

|---|

| Bucket widths | Shipping weight 9 in. (228 mm) - 70 lb (32 kg) 12 in. (305 mm) - 82 lb (37 kg) 16 in. (406 mm) - 92 lb (42 kg) 18 in. heavy duty (457 mm) - 106 lb (48 kg) 20 in. (508 mm) - 106 lb (48 kg) 24 in. (610 mm) - 120 lb (54 kg) 9 in. (228 mm) 12 in. (305 mm) 16 in. (406 mm) 18 in. heavy duty (457 mm) 20 in. (508 mm) 24 in. (610 mm) |

|---|

| Name | Link |

| View Product Brochure | Download |