- Monday 8:30 AM - 5:00 PM

- Tuesday 8:30 AM - 1:00 PM

- Wednesday Closed

- Thursday Closed

- Friday Closed

- Saturday Closed

- Sunday Closed

2024 John Deere 6080A

↵

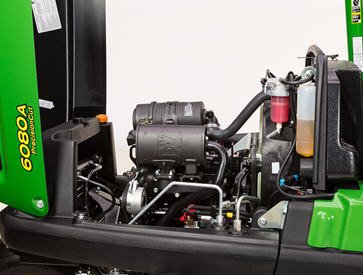

- 24.7 hp FT4 compliant Liquid-Cooled Diesel Engine

- 18” QA5 Cutting Units for an 80” total Width of Cut

- 3-wheel, smooth tire configuration with standard GRIP All-Wheel Drive

- Passcode-protected TechControl display

|

|

Ninety percent of all hydraulic leaks occur in the reel hydraulic circuit, mainly due to the necessity of having flexible hoses extending from the front of the machine for the front reels. These hoses see a lot of flexing during the mowing day as cutting units are raised and lowered. Cutting units also steer and float to follow undulations, increasing fatigue for the reel motor hoses. The 6080A, 6500A, 7500A, and 8000A E-Cut™ Hybrid Fairway Mowers have eliminated all reel circuit leak points by removing all hydraulics from the cutting unit drive circuit. This has eliminated the following hydraulic components:

Fewer hydraulic components leads to fewer leaks, increasing confidence that the finely manicured turf will not be damaged by hot hydraulic oil spilled onto a playing surface before an important tournament. |

|

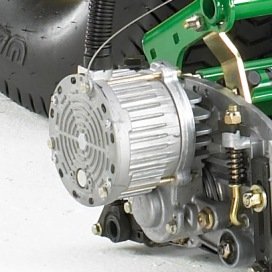

The electric reel motors on the 6080A, 6500A, 7500A, and 8000A E-Cut™ Hybrid Fairway Mowers are brushless, allowing them to be compact in size, roughly equal to that of today's hydraulic reel motors. The brushless motors are very efficient, leading to years of optimal performance with very minimal maintenance, and sealed for protection from the elements. A poly-chain belt connects the motor shaft to the reel and rotates the reel when the cutting units are engaged. The internal components of the motor are sealed for long life, durability, and protection from the elements. Cutting units are easily removed from the cutting unit motors by loosening the two bolts securing the motor to the cutting unit, turning the motor approximately a quarter turn, and pulling the motor from the cutting unit. This can be done in a matter of seconds. A tether prevents damage to the wiring harness when the motor is removed. |

|

The reel circuit is powered by a 48-V, 180-amp alternator belt-driven by the engine. The alternator supplies constant power to the reel circuit and only generates 48 V when the mow system is engaged. Due to this design, no additional batteries are required to drive the reel motors on the 6080A, 6500A, 7500A, and 8000A E-Cut™ Hybrid Fairway Mowers. With traditional electrical mowing systems, the frequency of clip would change as the batteries drained while mowing. A battery pack begins to lose its power immediately when used, but not on the E-Cut Hybrids. Since they still use an engine to drive an alternator, the frequency of clip at the start of the day and at the end of the day is exactly the same, yielding unparalleled quality of cut from start to finish. Plus, the machine doesn't have to be plugged in to charge the batteries once the day's mowing is done. The only limitation on run time with the E-Cut Hybrids is making sure the operator starts the day with a full fuel tank, just like with any other gas- or diesel-powered machine on the market today. The alternator only supplies power to the reel circuit. The remainder of the circuits are powered by a 12-V battery. |

|

The 6080A, 6500A, and 6700A PrecisionCut™ and 6080A, 6500A, and 8000A E-Cut™ Hybrid Fairway Mowers help to make fairways that look like greens a reality. |

|

MORE CONTROL WITH THE TECHCONTROL DISPLAY WITH A LARGE EASY-TO-READ SCREENPasscode-protected TechControl display enables quickly setting or changing mowing speed, turning speed, or transport speed to limit variations in performance by different operators. |

|

LoadMatch is an electronic setting through the TechControl display that allows managers more control of the machine and how it is operated when out on the course. Most operators will mow as fast as the mow setting will allow, keeping their traction pedal all the way down. However, in some conditions this can lead to poor cut quality. One example is getting behind in mowing due to weather conditions. The grass is long and lush and to properly cut that amount of grass at one time, the operator should slow the traction speed. This allows the cutting units to maintain proper turning speed, process the grass, and properly cut in one pass. Not slowing down causes missed grass and an uneven appearance. This affects the after-cut appearance and also reduces productivity by having to mow a second time to properly cut the lush grass. The LoadMatch feature compensates the traction speed of machine to keep power to the cutting units. In the long, lush conditions described above with LoadMatch engaged, the operator would still have the traction pedal all the way down, but the machine would sense the load and slow the traction speed to properly cut the mowing pass. Once the load is reduced, the machine will return to the normal mow speed. |

|

The traction system in the A-models is driven by a servo-controlled hydrostatic pump. The control of the pump is no longer mechanical linkages, but instead it is electronic. In total, approximately 94 parts have been eliminated from the traction drive system along with four adjustments compared to prior models. The design reduced the complexity of the drive system, which means no more linkages to adjust or repair, decreased routine maintenance, and more reliable day-in/day-out operation. |

|

The standard GRIP all-wheel drive traction system transfers hydraulic flow from wheels that slip to wheels that grip. For example, if the right front wheel starts to slip, hydraulic flow goes to the left front and rear tires to maintain traction power. This helps provide maximum traction in undulating conditions. The GRIP all-wheel drive traction system is standard equipment with the 6080A, 6500A, and 6700A PrecisionCut™ and 6080A and 6500A E-Cut™ Hybrid Fairway Mowers and is also engaged at all times, whether in mow or in transport. A check valve in the rear motor puts the machine in two-wheel drive (2WD) in reverse to minimize any potential scuffing. |

|

For superintendents who want stripes as straight as they are on the greens, the A-model PrecisionCut™ Mowers and E-Cut™ Hybrid Mowers do exactly that. Utilizing the same style steering cylinder as on the 2550 PrecisionCut and 2550 E-Cut Hybrid Riding Greens Mowers, the PrecisionCut and E-Cut Hybrid Mowers can mow the straightest lines of any mower in the industry today. Traditional hydraulic cylinders have a rod on only one side of the cylinder. The cylinder on the A-models has one rod that goes through both sides of the cylinder. This equalizes volume and pressure on both sides of the cylinder packing, helping the operator make perfectly straight lines with little effort. This system also equalizes the steering effort, meaning easy turns whether turning to the right or to the left. |

|

Easier daily maintenance points are designed into the machine to assist operators with complete daily maintenance and to keep the machine running at peak performance, saving valuable time and money. For ease of service, all daily engine checks are easily accessible by raising the hood. These service points include an engine-oil level check, a coolant level check, hydraulic fluid level, and an air-restriction indicator. The A-model PrecisionCut™ Mowers, E-Cut™ Hybrid Mowers, and TerrainCut™ Mowers feature a radiator screen that is easily removed without tools and a tilt-out oil cooler for easy cleaning. |

|

The 6080A PrecisionCut™ and 6080A and 8000A E-Cut™ Hybrid Fairway Mowers have cutting units that contact up stops for transport. These up stops are rubber and limit cutting units from swinging during transport to protect the cutting units when transporting down cart paths or bumpy terrain. |

| Maximum rated horsepower | At 3000 rpm: 24.7 hp (18.4 kW) High idle 3200 rpm |

|---|---|

| Drive pump | Axial piston, electronically controlled hydrostatic traction pump; dual gear pumps for steering, lift, mow, and charge |

| Ground pressure | 69 kPa 10 psi |

| Throttle | Hand throttle |

| Operator display | TechControl Display; Located on Command Arm; displays machine warnings, on-board electrical diagnostics; service timers on large easy to read screen; quick on the go settings for mow and transport speed; Turn Speed; Loadmatch™ and ON/OFF Cruise Control Use selection: all settings are pass code protected |

| Mowing speed | 0 to 12.8 km/h 0 to 8.0 mph |

| Cutting unit size | Quick Adjust QA5: 45.7 cm 18 in. |

| Total width of cut | 203 cm 80 in. |

| Reel diameter | 12.7 cm 5 in. |

| Frequency of clip (FOC Reels) OR Blade tip speed (decks) | 11- Blade: 0.69 mm/km/h 11- Blade: 0.044 in./mph 7-Blade: 1.09 mm/km/h 7-Blade: 0.069 in./mph |

| Type | Indirect Inject Diesel |

|---|---|

| Compliant emission regulation | United States and Canada Final Tier 4, EU Stage V |

| Horsepower | Maximum rated horsepower At 3000 rpm: 24.7 hp (18.4 kW) High idle 3200 rpm |

| Cylinders | Three |

| Displacement | 1.267 L 77.32 cu in. |

| Air cleaner | 2-stage dry element |

| Fuel | Diesel Up to B20 compliant |

| Cooling system | Liquid centrifugal pump; forward machine location for optimum cooling |

| Drive pump | N/A due to Electric Driven Cutting units |

|---|---|

| Hydraulic system capacity | 37.8 L 10 U.S. gal. |

| Fuel tank capacity | 45.4 L 12 U.S. gal. |

| Steering | Hydraulic power with double acting steering cylinder |

| Front drive tires | 24x13x12 smooth |

| Steering tires | 24x13x12 smooth |

| Ground pressure | 69 kPa 10 psi |

| Brakes | Internal hydraulic wet disc brakes with dynamic braking through closed loop hydrostatic system |

| ROPS | Standard; meets ISO 21299 Standard |

| Throttle | Automatic controls with AutoPedal foot controls; manual control through TechControl display |

|---|---|

| Forward/reverse | 2-pedal |

| Mower lift | One-touch single handle |

| Parking brake | Electric Switch on Command Arm for Internal Wet Disk Brakes |

| Seat | Suspension seat with seat belts and arm rest; fore/aft adjustment; weight and lumbar adjustment |

| PTO | Electric Switch on Command Arm |

| Tilt steering | Left Foot operated for easy adjustment |

| Height with ROPS | 215.3 cm 84.8 in. |

|---|---|

| Length | 305 cm 120.1 in. |

| Transport width | 232 cm 91.3 in. |

| Mowing position width | 233 cm 91.7 in. |

| Ground speed | Mowing 0 to 12.8 km/h 0 to 8.0 mph 4WD mow speed N/A Transport 0 to 16.1 km/h 0 to 10.0 mph Reverse 0 to 9.7 km/h 0 to 6.0 mph |

| Number | Five |

|---|---|

| Size | Quick Adjust QA5: 45.7 cm 18 in. |

| Total width of cut | 203 cm 80 in. |

| Height of cut | Construction Requires option bedknife for lowest HOC and 76.2 mm (3 in.) roller for highest: 2-28.5 mm 0.078-1.125 in. |

| Frequency of clip (FOC Reels) OR Blade tip speed (decks) | Rollers Front and rear: 51 in. 2 in. Optional: 76.2 mm 3 in. 11 Blade: 0.69 mm/km/h 0.044 in./mph 7 blade: 1.09 mm/km/h 0.069 in./mph |

| Reel diameter | 12.7 cm 5 in. |

| Measuring standard | ISO 11201 |

|---|---|

| Attachments installed | Fairway tender conditioners, reels engaged |

| Type | Two-year limited |

|---|

| Type | ANSI B71.4-2012 |

|---|